The stainless steel sculpture is a kind of modern art form. Contemporary large stainless steel sculptures have a variety of novel design styles, so they are deeply loved by people. Moreover, stainless steel sculptures have a variety of surface treatment methods. Different surface treatment methods show different effects. This gives customers more choices. Now we will introduce you to six common stainless steel sculpture surface treatments.

High Polish

The mirror treatment of stainless steel is to polish the stainless steel sculpture’s surface. A bright surface effect is obtained by rough grinding, medium grinding, and fine grinding using a high-quality whetstone, diamond grinding paste, and different sandpapers on polishing and grinding equipment. Polishing methods are divided into physical polishing and chemical polishing. Partial polishing can also be performed on the stainless steel surface. The polishing grades are divided into ordinary polishing, ordinary 6K, fine grinding 8K, and superfine grinding 10K effect. The mirror surface gives people a sense of high-end simplicity and a fashionable future. The mirror stainless steel sculpture placed in the garden could reflect the surrounding flowers and plants, giving people a visual aesthetic. For example, our metal water drop cobblestone design statue is so beautiful.

Brushed Treatment

Metal brushed treatment is a very common decoration method in life. The brushed treatment process, also known as frosting, is usually processed by mechanical friction on the surface of the stainless steel to obtain a straight line on the surface. Its surface is matte, and if you observe it carefully, you could see that there are traces of veins on the surface of the stainless steel, but you can’t feel it by hand. The brushed stainless steel is more wear-resistant than the mirror stainless steel, and it looks more upscale. This brushed surface treatment of stainless steel sculptures gives people the characteristics of good hand feeling, delicate luster, and strong wear resistance. For example, our brushed abstract stainless steel sculpture has won the love of countless customers.

Matte

The sandblasting process uses compressed air as a power source to convert the spray material into a high-speed jet beam and spray it onto the surface to be treated so that the surface of the stainless steel plate changes. Due to the impact and cutting action of the abrasive on the surface of the stainless steel plate, the surface obtains a certain degree of cleanliness and different roughness, and also improves its mechanical properties, thus improving its fatigue resistance and prolonging the durability of the stainless steel coating. It is also beneficial for the leveling and decoration of paints. The sandblasting process creates the low profile, aesthetics, and durability of the stainless steel sculptures. For example, our stainless steel water fountain has high quality and could be used for a long time.

Spray Coating

Spray coating is also known as thermal spraying. The technology of spraying the molten state of the spray material to the surface of the metal, alloy, and other workpieces with a power device to form a complete covering layer. When spraying, the stainless steel material is melted or softened by a heat source, and the molten droplets are atomized or pushed into a jet beam by the heat source’s own power or an externally compressed airflow and sprayed onto the stainless steel surface at a certain speed to form a coating. Stainless steel is sprayed to improve its corrosion resistance, heat resistance and wear resistance, increase its thickness or repair size, etc. The Mily factory has a lot of stainless steel sculptures in the spray series. For example, our balloon dog stainless steel sculpture, balloon flower stainless steel sculpture, etc. The surfaces of these stainless steel sculptures are sprayed to give a premium feel. These sprayed stainless steel sculptures are also our hot selling products.

Coated Plating

Coating plating is a method of coating a conductor with a layer of metal using the principle of electrolysis. Electroplating is divided into chrome plating, zinc plating, copper plating, nickel plating, etc. The main uses of electroplating include preventing metal oxidation (such as rust) and decoration. The outer layers of many coins are also electroplated. The most common type of electroplating is chrome plating, which creates a beautiful and shiny finish on the surface of the part. The surface layer of electroplated chrome is a bluish-white metallic color, which is not easy to change color and oxidize when exposed to the air.

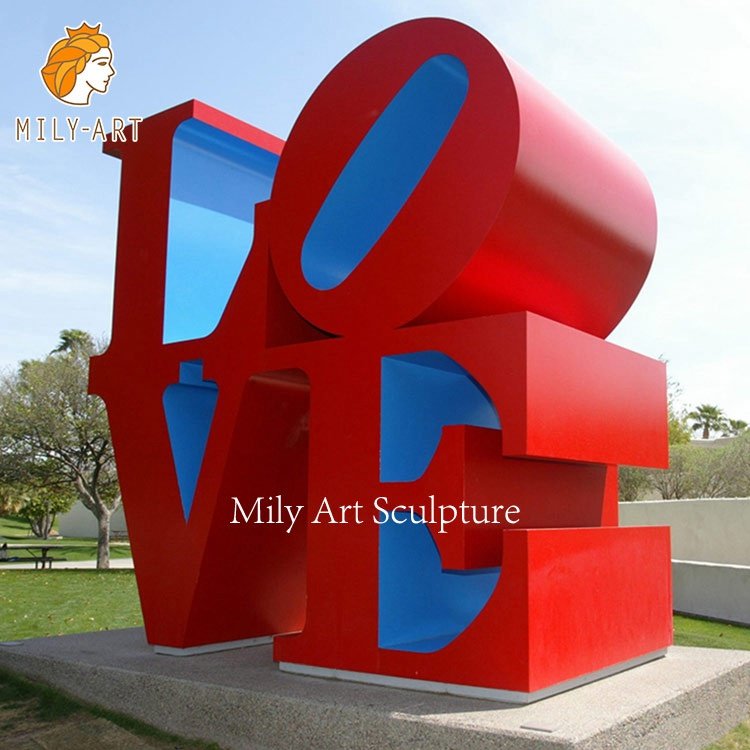

Car Painting

The surface of the stainless steel sculpture is clean and smooth, and the ordinary car painting method could also achieve a good surface effect. The Mily factory sprays the ED1000 epoxy primer first, then the topcoat is applied with a 24-hour interval between primers. Depending on the choice of use environment, the finish used in the indoor environment and outdoor environment is different. After a series of painting operations by professional masters, the surface of the stainless steel sculpture will show a strong color impact, giving people a strong visual experience. For example, Mily is able to create a highly reproducible copy of Love Sculpture. The large stainless steel sculpture we made is of high quality and uses high-quality automotive paint, giving a very high visual impact.

These different surface treatment methods have their own characteristics and produce very different surface effects. But no matter what kind of surface treatment it is, the top masters at the Mily factory could make it perfect. And they are quite suitable decorations for a garden, park, lawn, square, or in front of a shopping mall. We promise that wherever you place these stainless steel sculptures, they would become an attractive landscape and attract people’s great attention.

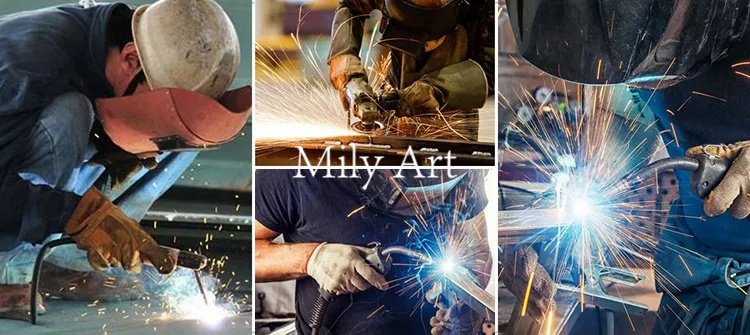

Mily is a factory dedicated to sculpture production. Rich experience in sculpture production enables us to form a mature production system and strict production standards. Moreover, the masters of our factory lived in the famous sculpture town since childhood and began to learn sculpture craftsmanship in childhood. The superb production skills make the sculptures they produce extremely realistic and of high quality. In addition, the Mily factory has very innovative designers. Their large stainless steel sculptures are loved by people of all ages. Please come to Mily if you want to buy stainless steel sculptures. We are confident to provide you with a satisfactory large stainless steel sculpture.